The high efficiency

separator QDK-S

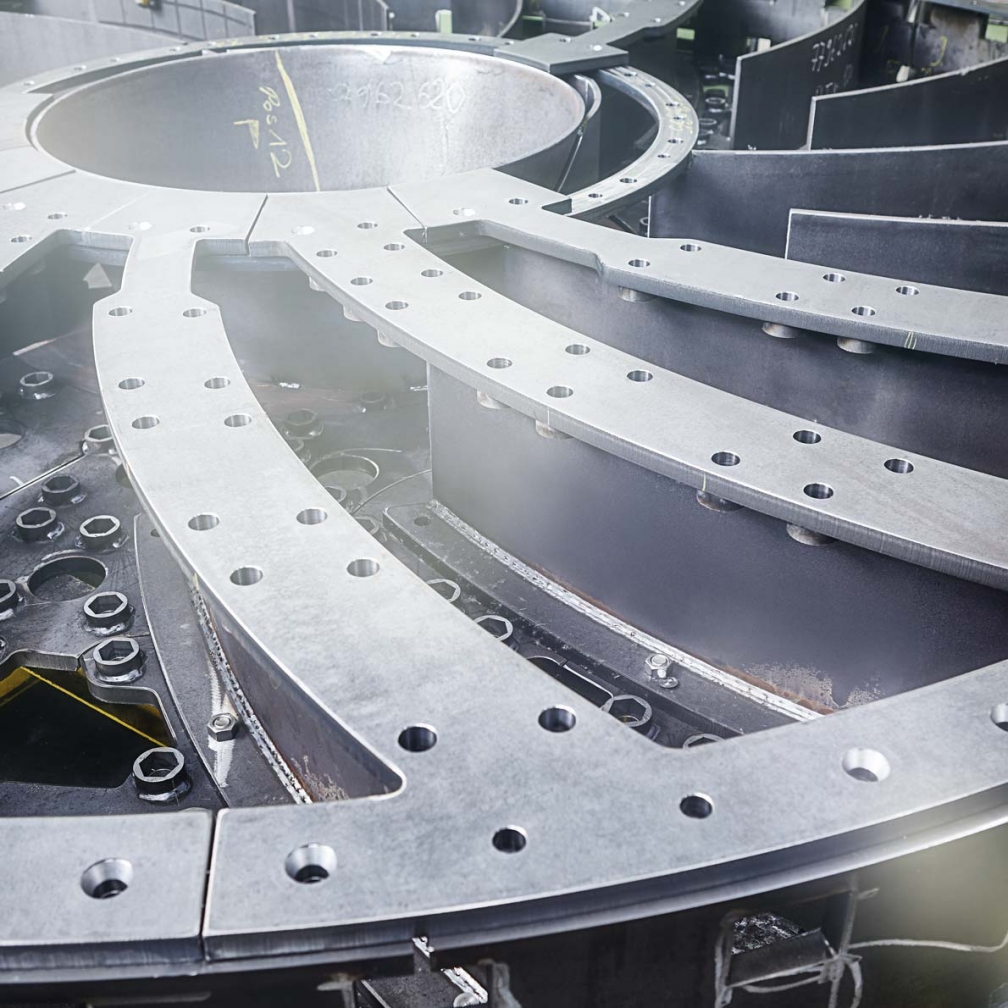

QDK-S cross-flow rotating cage separator

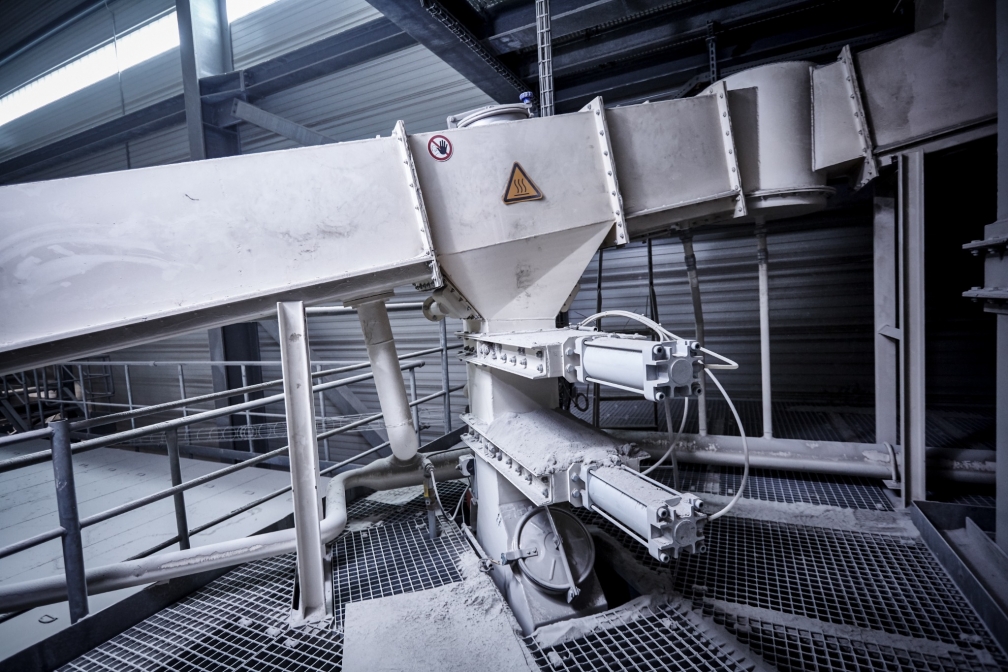

A separator for every need. It is no surprise that the proven QDK high efficiency separator is the most popular product in our OptiTromp family. The standard version of the cross-flow rotating cage separator can be integrated into almost any grinding plant. Top cuts of up to 10 µm can be produced, thanks to the particularly constant separating conditions within the entire separating zone.

Technical details

- High efficiency separator from the OptiTromp family

- Top cut up to 10 µm

- Constant separating conditions within the entire separating zone

- Air flow and speed of the rotating cage can be adjusted according to the required finish product

- Standard version fits nearly every grinding plant

- Circulation fans and cyclones ensure consistent optimization of the finish product output

- Alternative filter for finish product recovery: cooling of products and grits possible to 70°C

- Avoidance of oversized particles due to wear-free confined air seal of rotating cage

- Convenient maintenance thanks to large inspection doors for easy access to motor and bearing cartridge

more than 1,000 installations worldwide

What is the function of a separator?

The separator classifies the material stream into two partial streams depending on the particle size. The separator is charged with powdered material, consisting of particles of different sizes, in a continuous process. It defines the finer particles as the finish product by selecting them from the feed material. The rejected coarse particles and the non-selected fine particles are fed out of the separator as a second mass flow.

What is the function of the jalousy ring in classifiers with a rotating basket?

The jalousy ring serves as a static pre-classification device to define the amount of material passing to the rotating cage. At the same time, it limits the space around the rotating cage which makes it easier to adjust the flow conditions.

What does the term "loading factors" mean?

We often talk about two loading factors with regards to the separator. The feed loading and the fines loading in [kg/m³]. It means the mass of the respective fraction per air volume.

The higher the permissible loading factors, the smaller the separator can be designed to classify the required tonnages. Permissible loading factors mean the lowest value under which a separator can still effectively and reliably fulfill its function. Coarse material loading is not relevant in this context because it has no influence on the functionality of the separator.

Get your 360°Mill Check now!

The elimination of bottlenecks can lead to significant energy savings.

Let's find your bottlenecks.

AT YOUR SITE. WITH SERVICE EXCELLENCE FOR NEW AND EXISTING PLANTS.

Precise analysis for the perfect result.

We analyse your product to design the most efficient grinding plant.

- Technology center for material tests

- Laboratory for material analysis

Efficiency in grinding is our heritage and our future.

Since 1925.

Making grinding processes as efficient as possible is a science in itself – one to which we dedicate our entire expertise and spirit of innovation. From the invention of the first MONOBLOC diaphragm to the technical fine-tuning of the separator QDK. How we became what we are today.